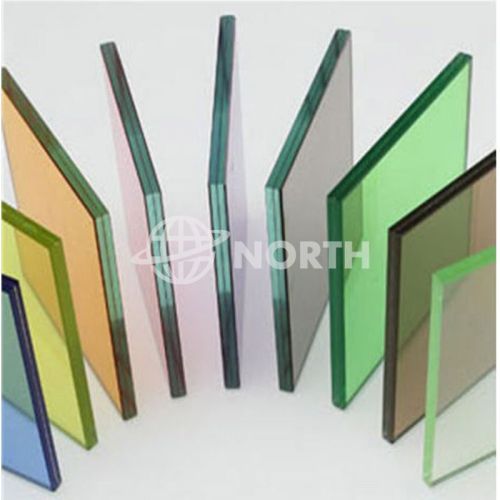

colored laminated glass

Product Description

colored laminated glass

https://www.chinanorthglass.com/product-colored-security-reflective-laminated-glass.html

Colored Security Reflective Laminated Glass, Solar Control Reflective Laminated Glass

Colored laminated glass is very similar to clear laminated glass, but with the addition of colored interlayers. These allow for a rich palette of color arrangements ranging from subtle transparent and translucent colors to opaque.

Colored Laminated Glass

Colored laminated glass is very similar to clear laminated glass, but with the addition of colored interlayers. These allow for a rich palette of color arrangements ranging from subtle transparent and translucent colors to opaque. Our colored laminates are manufactured using float glass as standard, but can also be made with specialty glass, including low iron (crystal clear) and a variety of body tones (blue, bronze and gray). The type and thickness of glass affects the color selected.

It is ideal for both structural and decorative applications, as the process offers a wealth of possibilities for a wide range of applications such as screens, partitions and cladding.

Laminated glass consists of two or more layers of glass that are bonded together with an intermediate layer by heat and pressure. In addition to this PVB (polyvinyl butyl) or EVA (ethylene vinyl acetate) interlayer, other materials such as colored interlayers, fabrics, metal mesh and digital prints can be included for a wide range of possibilities.

Lamination can also be combined with other decorative glass products and finishes such as kiln forming, sandblasting and color coating to further enhance the design.

The production of laminated glass is divided into three steps.

The initial lamination between glass and film takes place in a clean room.

The glass and film pass through a pre-lamination oven, where the temperature and pressure of the rollers increase the adhesion of the glass and film.

The final laminate is made in an autoclave under high pressure and temperature. Only then does the previously cloudy film gain its high transparency.

Today, colored laminated safety glass is often used in place of body-tinted glass made from colored paste. Instead of treating the glass itself, the color is introduced by means of a colored film bonded between two layers of glass.

The properties of the composite of glass, film and glazing are similar to those of conventional laminated safety glass, since the extruded colored film uses PVB as the raw material. As a result, more than a thousand transparent, translucent and opaque colors can be generated from eleven basic colors.