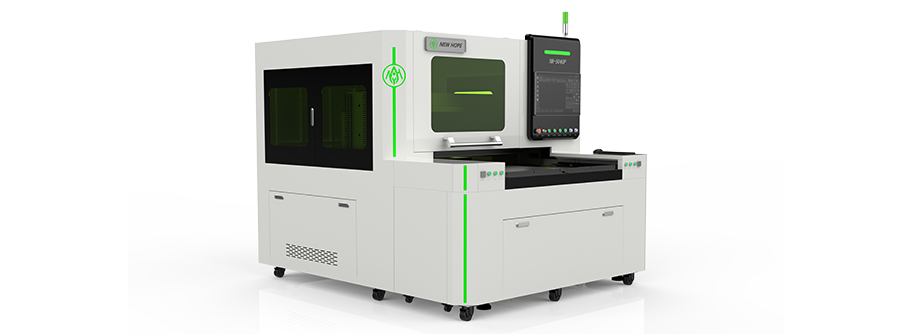

NH-5040P Picosecond glass cutting machine

Picosecond glass cutting machine

Product Description

Picosecond glass cutting machine

Equipped with high-precision marble platform base

Advantages of bed structure

The steel pipe welding foundation has high strength, the structure is more stable, and when cutting thick plates will not be deformed, ensuring the cutting accuracy of the equipment.

The high-strength aviation aluminum crossbeam and precision manufacturing process ensure the dynamic performance, accuracy, and stability of the machine during operation.

Technical Parameter

| Machine model | 5040P |

| Work area | 500mm*400mm |

| Max speed | 500mm/s |

| Positioning accuracy | ±0.002mm/m |

| Repeat positioning accuracy | ±0.002mm |

| Processing thickness | ≤12mm |

| Structure | Sheet metal welding cabinet, marble base, linear motor drive |

| Laser Type | Infrared picosecond/green light picosecond/ultraviolet picosecond |

| Adaptation power | 20W-70W |

Product Features

1. Equipped with high-precision marble platform base, linear motor drive, precise positioning and high stability.

2. Suitable for cutting and forming materials in industries such as circuit boards, sapphire, optical glass, vehicle panels, camera modules, etc.

3. Extremely high processing flexibility, can perform fine cutting of any shape, and the cutting edge is neat and without notches.

4. Non-contact processing, no maintenance required, solves industry problems.

5. Extremely high single pulse energy, achieves fine processing of most solid materials.

A cnc metal sheet cutting machine is a computer-controlled tool designed to cut, shape, and engrave metal sheets with extreme precision. By using programmed instructions (G-code) from CAD/CAM software, it controls cutting tools such as lasers, plasma torches, and mechanical blades. This process allows for highly accurate cuts, making it indispensable for industries requiring tight tolerances and intricate designs.