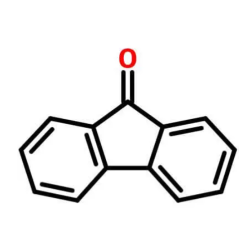

Rubber Anti-Scorching Agent PVI(CTP)

Rubber Anti-Scorching Agent PVI(CTP)

Product Description

With the development of production and the improvement of rubber product performance in the rubber industry, the problem of increased heat generation during rubber processing has emerged. Therefore, ensuring safety during the processing has become a very important issue. The main method commonly used now is to add a small amount of anti scorching agent (also known as anti scorching agent or retardant) during the processing to improve the safety of the processing and increase the storage life of the rubber material or slurry. When adjusting the vulcanization system is difficult to achieve the required operational safety, adding anti coking agents can often easily meet the requirements for the coking performance of the rubber material. Although the amount of anti scorching agent used is very small, it has some adverse effects on the performance of the rubber material when added, so it is generally not used as much as possible.

|

Item |

Index |

|

Acceptable end-product |

|

|

Appearance (Visual inspection) |

White powder or granular |

|

Initial Melting Point,℃≥ |

89.0 |

|

Loss on Drying % ≤ |

0.50 |

|

Ash % ≤ |

0.10 |

|

Toluene insoluble,% ≤ |

0.50 |

It can be used for natural rubber and synthetic rubber. It can effectively prevent the rubber material from scorching during processing and improve production efficiency. At the same time, it has a restorative effect on rubber materials that have experienced high heat or are slightly scorched. N-cyclohexylthiophthalimide is widely used in sulfur-vulcanized elastomers and has good anti-scorch effects when used with various general accelerators. Equipped with the anti-scorch agent CTP, whether it is open or high-temperature rapid internal mixing, a one-stage mixing process can be used to effectively prevent scorch. It can be used together with accelerator M, DM, TMTD and effective or semi-effective vulcanization system to improve rubber properties. It can improve the production efficiency of calendering and extrusion. It is beneficial to improve the adhesion between rubber and brass-plated steel wire. It is widely used in various general-purpose rubbers and special rubbers including nitrile rubber, ethylene-p